| Article No. | : | | 1708 XS3 | POLYKNIT MONO ELASTIC |

| | | | | | | |

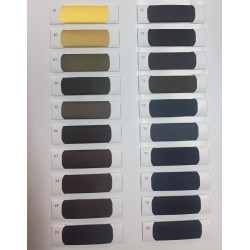

| Colour | : | 105 = Natural, 990 = Black | | |

| | | | | | | |

| Weight, approx. | : | approx. 40 g/m2 | | |

| | | | | | | |

| Width | : | approx. 150 cm | | |

| | | | | | | |

| Roll length | : | approx. 120 m | | |

| | | | | | | |

| Composition | : | 100% PES | | | | |

| | | | | | | |

| Warp | : | PES | | | | |

| | | | | | | |

| Weft | : | PES textured | | |

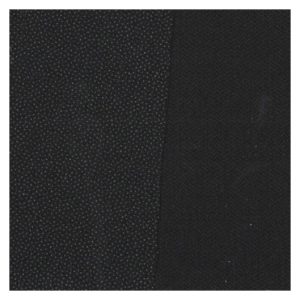

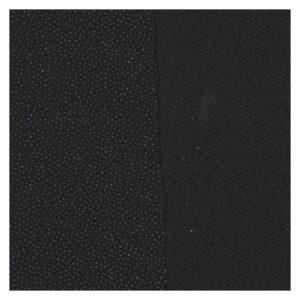

| Construction | : | plain fringe | | | |

| | | | | | | |

| Coating | : | micro random dot | | |

| | | Mesh: 21 points/cm2, approx. 76 |

| | | | | | | |

| Care Label | : | | |

| | | |

| Weft-insert with textured weft for light-weight manufacture in ladies and menswear. |

| Whatever the weight of the outer – be it silk, viscose, cupro, acetate, micro-fibres, |

| velvet or mohair – its characteristics remain unchanged. You obtain a good peel |

| strength as this article is particularly adapted to outer fabrics which are difficult to |

| | | | | | | |

| be fused. Ideal for mono-elastic outers. If double lamination is required please fuse |

| warp to warp / weft to weft. Thus the best possible handle and support will be |

| | | | | | | |

| obtained. Also available as tape. The chest reinforcement should NOT be fused on |

| the bias. Corresponds to TL 8305-0210/5 – interlining light of the German Federal |

| Armed Forces (BWB). | | | | | |

| | | | | | | |

| | Glue-line temperature | | Pressure | | Fusing time |

| Recommended | | | | | | | |

| Fusing Conditions | | 121 – 132 0 C | | | 2 – 4 bar | | 10 – 16 s |

| | 250 – 270 0 F | | | 200 – 400 p/cm2 | | |

| | | | | 15 – 30 N/cm2 | | |

| | | | | | | |

| Results will vary according to the type of fabric used, and the model of the fusing press. |

| For this reason pre-production testing is essential | |